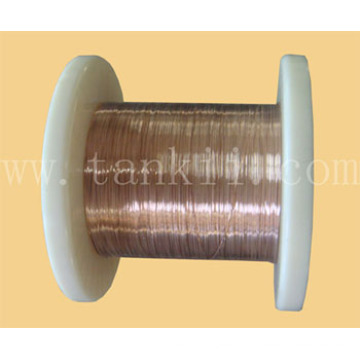

CuNi6 Copper Nickel Wire (C70400)

Basic Info

Model No.: C70400

Product Description

Model NO.: C70400 Sample: Sample Available Resisivity: 0.12milliohm/M Density: 8.9(g/cm3) Transport Package: Packing in Coil Cartons, Pallet, Spools, Coils Origin: China Serves: Small Order Accepted Other Name: Nco10 Melting Point: 1095 Trademark: TANKII Specification: B267 HS Code: 74082200

As a big manufacturer and exporter in China on the line of electric resistance alloy, we can supply all kinds of electric resistance alloy wire and strips (resistance steel wire and strips),

Material: CuNi1, CuNi2, CuNi6, CuNi8, CuNi14, CuNi19, CuNi23, CuNi30, CuNi34, CuNi44

General Description

Due to has high tensile strength and increased resistivity values, TANKII copper nickel alloy wires are the first choice for applications as resistance wires. with the different nickel amount in this product range, the characteristics of the wire can be chosen according to your requirements. Copper nickel alloy wires are available as bare wire, or enamelled wire with any insulation and self-bonding enamel. Furthermore, litz wire made of enamelled copper nickel alloy wire are available.

Features

1. Higher resistance than copper

2. High tensile strength

3. Good bending proof performance

Application

1. Heating applications

2. Resistance Wire

3. Applications with high mechanical requirements

4. Others

Size

Wires: 0.018-10mm Ribbons: 0.05*0.2-2.0*6.0mm

Strips: 0.05*5.0-5.0*250mm Bars: D10-100mm

Contact us if you need more details on Cuni6 Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Copper Nickel Alloy Wire、Precision Resistance Alloy Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

As a big manufacturer and exporter in China on the line of electric resistance alloy, we can supply all kinds of electric resistance alloy wire and strips (resistance steel wire and strips),

Material: CuNi1, CuNi2, CuNi6, CuNi8, CuNi14, CuNi19, CuNi23, CuNi30, CuNi34, CuNi44

General Description

Due to has high tensile strength and increased resistivity values, TANKII copper nickel alloy wires are the first choice for applications as resistance wires. with the different nickel amount in this product range, the characteristics of the wire can be chosen according to your requirements. Copper nickel alloy wires are available as bare wire, or enamelled wire with any insulation and self-bonding enamel. Furthermore, litz wire made of enamelled copper nickel alloy wire are available.

Features

1. Higher resistance than copper

2. High tensile strength

3. Good bending proof performance

Application

1. Heating applications

2. Resistance Wire

3. Applications with high mechanical requirements

4. Others

Size

Wires: 0.018-10mm Ribbons: 0.05*0.2-2.0*6.0mm

Strips: 0.05*5.0-5.0*250mm Bars: D10-100mm

| Characteristic | Resistivity ( 200C μ Ω . m) | Max. working Temperature ( 0C) | Tensile Strength (Mpa) | Melting point (0C) | Density ( g/cm3) | TCR x10-6/ 0C (20~600 0C) | EMF vs Cu (μ V/ 0C) (0~100 0C) |

| Alloy Nomenclature | |||||||

| NC003 (CuNi1) | 0.1 | 200 | ≥ 250 | 1095 | 8.9 | < 100 | -12 |

| Physical Properties | Metric | Comments |

| Density | 8.94 g/cc | |

| Mechanical Properties | Metric | Comments |

| Tensile Strength, Ultimate | 262 - 531 MPa | |

| Tensile Strength, Yield | 276 - 524 MPa | Depending on temper |

| Elongation at Break | 46.0 % | in 50.8 mm. |

| Modulus of Elasticity | 115 GPa | |

| Poissons Ratio | 0.310 | Calculated |

| Machinability | 20 % | UNS C36000 (free-cutting brass) = 100% |

| Shear Modulus | 44.0 GPa | |

| Electrical Properties | Metric | Comments |

| Electrical Resistivity | 0.0000120 ohm-cm @Temperature 20.0 ° C | |

| Thermal Properties | Metric | Comments |

| CTE, linear | 17.5 µ m/m-° C @Temperature 20.0 - 300 ° C | |

| Specific Heat Capacity | 0.380 J/g-° C | |

| Thermal Conductivity | 64.0 W/m-K @Temperature 20.0 ° C | |

| Melting Point | < = 1125 ° C | Liquidus |

| Liquidus | 1125 ° C | |

| Processing Properties | Metric | Comments |

| Annealing Temperature | 565 - 815 ° C | |

| Hot-Working Temperature | 815 - 950 ° C | |

| Component Elements Properties | Metric | Comments |

| Copper, Cu | > = 91.2 % | |

| Iron, Fe | 1.30 - 1.70 % | |

| Lead, Pb | < = 0.050 % | |

| Manganese, Mn | 0.30 - 0.80 % | |

| Nickel, Ni | 4.80 - 6.20 % | |

| Zinc, Zn | < = 1.0 % |

Product Categories : Copper Nickel Alloys > CuNi Resistance Alloys Wire

Other Products

Hot Products

Au-Cu Wire(AU80-CU20)Tankii manufacturingSeamless C10200 Oxyge- Free Copper Hollow Conductor TubesASTM B265 Gr2 Titanium SheetConstantan Konstantan Wire / CuNi44 WireCuNi6 Copper Nickel Wire (C70400)copper nickel Alloy Constantan Cupro-Nickel CuNi44 Strip/Foil/RibbonChromel Thermocouple wire or cable (type K)Nichrome Strip/Nickel Allloy SheetNickel Chrome Wire (NCHW) for ResistorD Resistance WireBright Annealed Fecral Alloy Strip for ResistorHot Sale Building Materials Aluminum Sheet / PlateHigh Quality Gr5 Round Titanium BarASTM B 338 Gr2 Seamless Titanium Tube/PipeChina Grade 304 316 316L 304L Capillary Stainless Steel Tube6061/6063 T5 Anodized Aluminum Pipe/Tubes