Molybdenum Wire for shifting fork coating

Basic Info

Model No.: Mo 99.95

Product Description

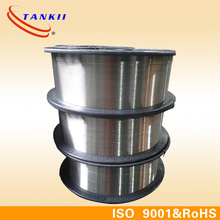

Model NO.: Mo 99.95 Standard: GB Alloy: Non-alloy Powder: Not Powder Density: 10.2 g/cm3 Application: Industrial Purity: >99.95% Type: Molybdenum Wire Tensile Strength: 850 N/mm2 Thermal Spray Molybdenum Wire

1. Two kinds of surface: 1) Black: Spray molybdenum wire surface coated with graphite milk, a more uniform black.

2) Bright: remove the graphite milk was bright.

2. The density is 10.2g/cm3

3. TANKII Molybdenum wire - 10kg single weight no welding point.

4.This product is used for the fine spraying of the surface and other mechanical wear parts of the automobile, so as to enhance its wear resistance.

5.Package: Spool/Coil, moisture-proof paper, paper carton

6.If you have special requirements, can be negotiated.

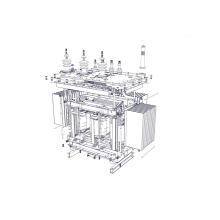

Thermal spray is a method to produce spray molybdenum wire. Thermal spraying is generic term used to define a group of processes that deposit finely divided metallic or nonmetallic materials onto a prepared substrate to form a coating. The coating material may be in powder, rod or wire form.

The thermal spray gun to produce spray molybdenum wire uses plasma arc, combustible gases or an electric arc to generate the heat necessary to melt the coating material. The material changes to a plastic or molten state when heated and is accelerated by process gases. The acceleration of the molten material produces a confined stream of particles that the process gases transfer to the substrate. The particles strike the substrate, flatten upon impact, and form thin platelets that bond to the substrate and to each other. The particles build up and cool into a lamellar structure that forms a coating.

The thermal spray process is synergistic. System components, parameters and the desired coating functions and properties must be determined to select the type of material and equipment needed for the process. The process may be tailored for particular application after establishing this information.

Various coatings can be achieved by using different combinations of equipment and consumables. Basic thermal spray producing spray molybdenum wire systems typically consist of a spray gun, powder supply or gas control console and a wire or powder feeder.

Thermal spray processing is a well established way of forming coatings of thicknesses greater than about 50 micrometers, so-called thick coatings. A wide range of materials can be thermal sprayed for a variety of applications, ranging from gas turbine technology (heat engines) to the electronics industry.

Contact us if you need more details on molybdenum wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about shifting fork coating、thermal spraying molybdenum wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

| Chemical Element(%)/Grade | TMo-1 | TMo-2 | |

| Mo | ≥99.95 | ≥99.95 | |

| Other Elements(ppm) ≤ | C | 30 | 80 |

| Ag | 5 | - | |

| Al | 20 | 20 | |

| As | 5 | - | |

| Ba | 10 | - | |

| Ca | 20 | 20 | |

| Co | 30 | - | |

| Cr | 20 | - | |

| Cu | 10 | - | |

| Fe | 60 | 60 | |

| Mg | 10 | 10 | |

| Mn | 10 | - | |

| Ni | 10 | 10 | |

| Na | 10 | - | |

| Nb | 10 | - | |

| O | 50 | 60 | |

| P | 20 | - | |

| Pb | 10 | - | |

| S | 20 | - | |

| Si | 10 | 30 | |

| Ta | 20 | - | |

| Ti | 10 | 10 | |

| W | 100 | 300 | |

| Zn | 5 | - | |

| Zr | 5 | - | |

| Diameter (mm) | Tolerance | Single wire weight (kg) | Single wire length (m) | Spool flange diameter (mm) | Tensile strength (Mpa) | Elongation rate(%) |

| 1.41~1.51 | -0.04~+0 | 4~10 | 250~600 | 450~600 | 850 | 5 |

| 1.51~1.62 | -0.04~+0 | 4~10 | 220~480 | 450~600 | 850 | 5 |

| 1.91~2.00 | -0.04~+0 | 5~12 | 170~380 | 450~600 | 850 | 5 |

| 2.21~2.30 | -0.05~+0 | 5~12 | 130~280 | 450~600 | 800 | 5 |

| 2.31~2.40 | -0.05~+0 | 6~12 | 130~350 | 600 | 800 | 5 |

| 3.10~3.18 | -0.054~+0 | 6~12 | 80~200 | 600 | 700 | 5 |

1. Two kinds of surface: 1) Black: Spray molybdenum wire surface coated with graphite milk, a more uniform black.

2) Bright: remove the graphite milk was bright.

2. The density is 10.2g/cm3

3. TANKII Molybdenum wire - 10kg single weight no welding point.

4.This product is used for the fine spraying of the surface and other mechanical wear parts of the automobile, so as to enhance its wear resistance.

5.Package: Spool/Coil, moisture-proof paper, paper carton

6.If you have special requirements, can be negotiated.

Thermal spray is a method to produce spray molybdenum wire. Thermal spraying is generic term used to define a group of processes that deposit finely divided metallic or nonmetallic materials onto a prepared substrate to form a coating. The coating material may be in powder, rod or wire form.

The thermal spray gun to produce spray molybdenum wire uses plasma arc, combustible gases or an electric arc to generate the heat necessary to melt the coating material. The material changes to a plastic or molten state when heated and is accelerated by process gases. The acceleration of the molten material produces a confined stream of particles that the process gases transfer to the substrate. The particles strike the substrate, flatten upon impact, and form thin platelets that bond to the substrate and to each other. The particles build up and cool into a lamellar structure that forms a coating.

The thermal spray process is synergistic. System components, parameters and the desired coating functions and properties must be determined to select the type of material and equipment needed for the process. The process may be tailored for particular application after establishing this information.

Various coatings can be achieved by using different combinations of equipment and consumables. Basic thermal spray producing spray molybdenum wire systems typically consist of a spray gun, powder supply or gas control console and a wire or powder feeder.

Thermal spray processing is a well established way of forming coatings of thicknesses greater than about 50 micrometers, so-called thick coatings. A wide range of materials can be thermal sprayed for a variety of applications, ranging from gas turbine technology (heat engines) to the electronics industry.

Contact us if you need more details on molybdenum wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about shifting fork coating、thermal spraying molybdenum wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Thermal Spray Wire

Premium Related Products

Other Products

Hot Products

Au-Cu Wire(AU80-CU20)Tankii manufacturingSeamless C10200 Oxyge- Free Copper Hollow Conductor TubesASTM B265 Gr2 Titanium SheetConstantan Konstantan Wire / CuNi44 WireCuNi6 Copper Nickel Wire (C70400)copper nickel Alloy Constantan Cupro-Nickel CuNi44 Strip/Foil/RibbonChromel Thermocouple wire or cable (type K)Nichrome Strip/Nickel Allloy SheetNickel Chrome Wire (NCHW) for ResistorD Resistance WireBright Annealed Fecral Alloy Strip for ResistorHot Sale Building Materials Aluminum Sheet / PlateHigh Quality Gr5 Round Titanium BarASTM B 338 Gr2 Seamless Titanium Tube/PipeChina Grade 304 316 316L 304L Capillary Stainless Steel Tube6061/6063 T5 Anodized Aluminum Pipe/Tubes