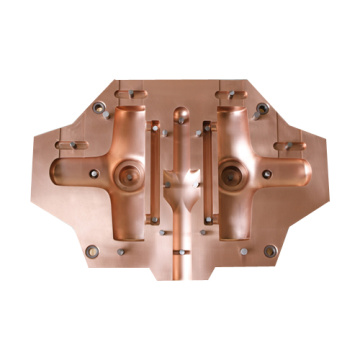

Beryllium Copper Alloys - High Strength Spring Copper

| Packaging: | standard export package |

|---|---|

| Productivity: | 10000kg/month |

| Brand: | Hitech |

| Transportation: | Ocean,Land,Air,Express |

| Place of Origin: | China |

| Supply Ability: | 10000kg/month |

| Certificate: | ISO, test reports |

| HS Code: | 7407290000 |

| Port: | Qingdao,Tianjin,Shanghai |

Basic Info

Model No.: C17200, C17510, C17500

Click on the follow link to find out more information: http://www.sdhitech.com/beryllium-copper/

Company Info

- Company Name: Shandong Hitech Metal Material Co., Ltd

- Representative: Wang Jinying

- Product/Service: High Purity Copper , Copper Alloy , Oxygen Free Copper , Bonding Wire Billets , Single Crystal Copper , Sputtering Target Materials

- Capital (Million US $): 10,000,000RMB

- Year Established: 2021

- Total Annual Sales Volume (Million US $): Below US$1 Million

- Export Percentage: 41% - 50%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 5

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: Fewer than 5 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: New Economic Industrial Park, Dongying City, Shandong Province, China

- Contact Person: Ms. 王

- Tel: +86-546-7766300

Premium Related Products

Other Products

Hot Products

Au-Cu Wire(AU80-CU20)Tankii manufacturingSeamless C10200 Oxyge- Free Copper Hollow Conductor TubesASTM B265 Gr2 Titanium SheetConstantan Konstantan Wire / CuNi44 WireCuNi6 Copper Nickel Wire (C70400)copper nickel Alloy Constantan Cupro-Nickel CuNi44 Strip/Foil/RibbonChromel Thermocouple wire or cable (type K)Nichrome Strip/Nickel Allloy SheetNickel Chrome Wire (NCHW) for ResistorD Resistance WireBright Annealed Fecral Alloy Strip for ResistorHot Sale Building Materials Aluminum Sheet / PlateHigh Quality Gr5 Round Titanium BarASTM B 338 Gr2 Seamless Titanium Tube/PipeChina Grade 304 316 316L 304L Capillary Stainless Steel Tube6061/6063 T5 Anodized Aluminum Pipe/Tubes